Isihluzi sepleyiti ye-Sinter-Uhlobo lwe-HSL-Ipleyiti ye-Sinter-Sintered yePlayiti-i-Sinter yePlayiti ye-Sinter-Plastiki eSintered Plate-Sintered Plate

Inkcazo yeMveliso

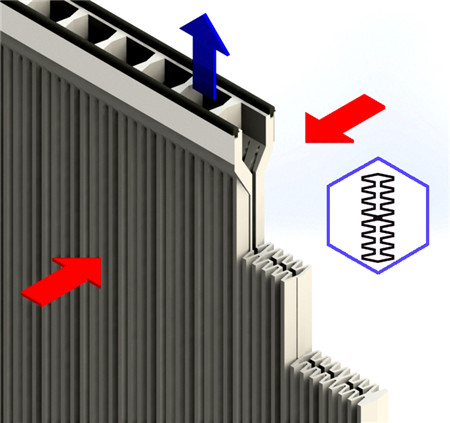

Isihluzo sepleyiti ye-Sinter luhlobo lozinzo lwemilo kunye nokuchasana okunamandla kwimpembelelo kunye nekhono lomthwalo wemathiriyeli yokucoca.Ikwabizwa ngokuba yi "plastic sinter plate".Ipleyiti yokucoca eqinileyo enematrix eyenziwe ngomgubo we-PE ngenkqubo ekhethekileyo ye-sinter, kwaye igqunywe nge-PTFE (eyaziwa ngokuba yi-"Plastiki yoKumkani", imathiriyeli yokugquma yembiza engeyiyo intonga).Ngenxa yokucoca umphezulu ococekileyo, uvimba uthuli ngaphandle kwezinto zokucoca kwaye kulula ukucocwa kumgca.Inokuchaneka kokucoca okunamandla, okunokuthi kusetyenziswe kwiindawo ezahlukeneyo zokushisa eziphezulu okanye eziphantsi, kwaye zinokusetyenziswa ngokuphindaphindiweyo, ukunciphisa ngokufanelekileyo iindleko zemveliso.

Iimpawu/Izinto eziluncedo

Uhlobo lwangaphambili lweSinter Plate yesihluzi seNqanaba (Yokutshintshwa):

HSL_1500/18

| Ke yintoni i-sinter plate?Ipleyiti ye-sinter apha ibhekisa kwipleyiti yokucoca eqinileyo enematrix eyenziwe ngomgubo we-PE ngenkqubo ekhethekileyo ye-sinter, kwayeigqunywe nge-PTFE (eyaziwa ngokuba yi "Plastiki King", imathiriyeli yokugquma yembiza engeyiyo intonga).Ngenxa yokuba izinto eziluhlaza ziyiplastiki zonke, ikwabizwa ngokuba yi "plastic sinter plate".Le teknoloji yavela eJamani, kwaye inakoyenza izihluzi ngeemilo ezahlukeneyo.I-PTFE yokwambathisa inokuthintela uthuli ngaphandle kwezinto zokucoca, njengesiphumo "sokucoca ubuso".Oku kwahluke kakhulu kwisiphumo "sokuhluzwa okunzulu" kwesihluzo sefayibha.Kweli nqanaba, kuphela i-media ye-membrane ye-membrane ekumgangatho ophezulu inokuthelekiswa nepleyiti ye-sinter, kodwa ukugquma kwepleyiti ye-sinter kungena nzulu kwi-matrix, kwaye akukho lula ukunxitywa kunye nokukrazulwa, kunye nezinye izibonelelo ezininzi. |

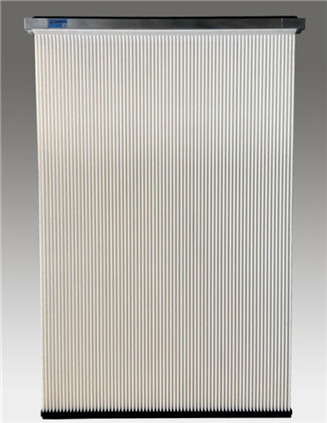

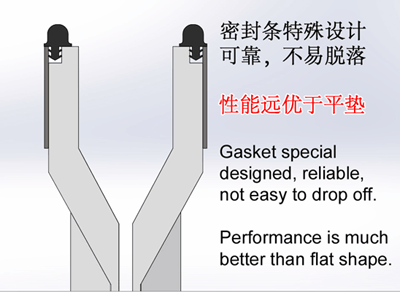

1. I-PE matrix + i-PTFE yokwambathisa, ukuhluzwa komhlaba okucocekileyo, ukukhutshwa kwe-ultra low, ukuxhathisa okuzinzileyo.2.Imathiriyeli ekrwada ethengwayo kumazwe angaphandle, iqinisekisa ukusebenza kakuhle okuphezulu, ngelixa ukuxhathisa okuphantsi, kunye nokumelana nokuguga kunye nokumelana nokuguga.3.Intloko yokucoca i-sintered yonke kunye, kunye nemilo ye-CNC eyenziwe ngomatshini, kunye nokuqiniswa kwepleyiti yensimbi engenasici, intloko yokucoca iqinile kwaye ithe tye.4.Umsesane we-Gasket uyilwe ngokukodwa, ufakwe kwi-CNC eyenziwe yokufakela i-slot, ethembekileyo, ehlala ixesha elide, kwaye akukho mfuneko yakukhathazeka malunga nokuyeka.

5. Umzantsi wokucoca uphoswe ngokupheleleyo, onokuthi utywinwe kakuhle, uqine kwaye uqine.

6. Ubunzima bungaphantsi kwe-18 kg, kulula ukuhamba nokugcina.

IJamani yeMveliso + yeMathiriyeli eNgeniswa kwamanye amazwe + iTekhnoloji entsha

Iqinisekiswe yilabhoratri yaseJamani.

Idatha yoBugcisa

Ubungakanani besihluzi

| Ubungakanani | Indawo yoHluzo (m2) |

| HSL_1500 / 18 | 7.64 |

Isihluzi semidiya

| Ipharamitha Ikhowudi yemidiya | NT1 | AT1 |

| Ukusebenza kakuhle | 99.999% @ 1μm | |

| Ukusebenza kweTemp. | 70℃ | 70℃ |

| Ukucoca Uxinzelelo Lomoya | 4.0 ~ 4.5 Ibha | |

| Ukunyangwa kokuvuza kwe-Electrostatic | N / A | ≤ 106Ω |

| A/C Umlinganiselo | 0.8~1.3 m/mz | |

| Ukumelana nomoya | 1500~2000 Pa (Kuxhomekeke kwiimeko zokusebenza) | |

| Uhlobo loFakelo lweGasket Ring | Irhasi ekrwada kuphela | |

* Nceda ubonise “Ubungakanani + MediaIkhowudi” xa uodola.

Umzekelo: iSinter Plate Filter Element, Uhlobo: HSL_1500/18 NT1.

Imimandla Esebenzayo

| Ishishini lentsimbi | I-Metallurgy engasebenziyo | Ushishino lweemoto | Ukwenziwa kweOre | Rubber Tire Industry |

| Ishishini le-Electronics | Foundry | Laser-Cutting | Ishishini lemichiza | Ikhemesti |

| Ukulungiswa kokutya | Imveliso yeglasi kunye neCeramics | Ishishini leSamente kunye neLime | Umsebenzi Wesinyithi | … |

-

iSinter Plate Filter Element (HSL1500/18)

iSinter Plate Filter Element (HSL1500/18)