Factory Free sample Herding Sinter Plate Filter - Cartridge-Sinter Plate Filter-Sinter Plate Dust Collector-Herding Sinter Plate Filter-Sintered Stainless Steel Filter Plate – Sinter Plate

Factory Free sample Herding Sinter Plate Filter - Cartridge-Sinter Plate Filter-Sinter Plate Dust Collector-Herding Sinter Plate Filter-Sintered Stainless Steel Filter Plate – Sinter Plate Detail:

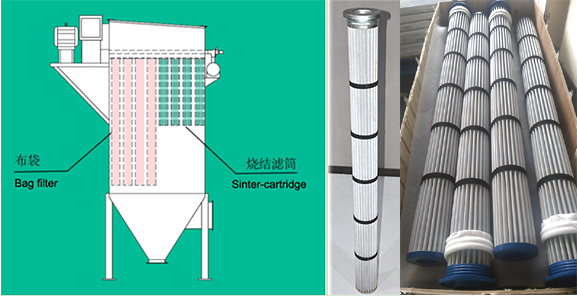

Combining the revolutionary materials of dry-filtration technology with bag filters: Sinter Cartridges. PE (polyethylene) porous matrix and PTFE embedded coating, pure surface filtration, efficient wear-resistant sinter plate filtration media with the wave-shaped cylindrical structure, the perfect alternative to bags and its cage.Using bag filter, it has the problems of discharge over standard, deducting air volume decreased and changing cloth bag frequently,ect. Through the simple and easy -to-use sinter cartridge, it is easy to solve these difficult problem.

Whether it is the dust with strong abrasion, or the ultra-fine dust, or even the wet working condition, the sinter-cartridge can handle it calmly.

For bag filter upgrade at minimum cost:

Sinter-Cartridge: LT Series

|

Reduce downtime.Reduce operation cost.Meet emission standards.Maximize dust collector capacity.Prolong dust collector service life. |

| Is the old bag filter not easy to use? | Does your bag filter discharge over standard? Has the dedusting air volume decreased significantly? Do you need to change cloth bags frequently? | We provide you with the appropriate solution, through the simple and easy-to-use sinter-cartridge, to solve your difficult problems. |

| Combination of revolutionary dry filtration technology material and bag filter: sinter-cartridge | PE porous matrix + PTFE embedded coating, pure surface-filtration, high-efficiency and wear-resistant sintered filter media, with wave shaped cylinder structure, perfectly replacing the cloth bag and cage; | 99.999% efficiency.Dealing with 0.1um particle.Emission<< 1mg / Nm3Self lubricating and hydrophobic material, easy to purgeNo fiber |

| Significant improvement in service life and efficiency | Whether it is the dust with strong abrasion, or the ultra-fine dust, or even the wet working condition, the sinter-cartridge can handle it calmly. | The sinter-cartridge made of advanced sintered filter media, which has high filtration efficiency, service life expectancy of more than 10 years, and consistent filtration performance. |

| Low cost, fast and simple | Select the sinter-cartridge and replace the bag filter directly without changing the structure of the original dust collector. | Reduce downtime, prolong dust collector service life. |

Filter Size

|

Size |

Filtration Area (m2) |

| LT125-1500 |

1.49 |

| LT125-750 |

0.73 |

| LT125-500 |

0.48 |

| * LT133-1500 |

1.62 |

| * LT133-750 |

0.80 |

| * LT133-500 |

0.53 |

| LT162-1500 |

2.03 |

| LT162-750 |

1.00 |

| LT162-500 |

0.66 |

* Recommended type. (Other types not on list can be customized.)

Filter Media

| Parameter Media Code |

NT1 |

AT1 |

NT2 |

AT2 |

| Efficiency: 99.999% @ 1μm |

● |

● |

● |

● |

| Operation Temp. |

70℃ |

70℃ |

100℃ |

100℃ |

| Electrostatic Leakage Resistance |

N/A |

≤ 106Ω |

N/A |

≤ 106Ω |

| A/C Ratio |

0.8~1.3 m/min |

|||

| Air Resistance |

1500~2000 Pa (Depends on operating conditions) |

|||

| Gasket Ring Installation Type |

Clean Gas |

|||

* Please indicate “Size + Media Code” when ordering.

Example: Sinter-cartridge, Type: LT133-1500 NT1.

| Steel Industry | Nonferrous Metallurgy | Automobile Industry | Ore Processing | Rubber Tyre Industry |

| Electronics Industry | Foundry | Laser-Cutting | Chemical Industry | Pharmacy |

| Food Processing | Glass and Ceramics Industry | Cement and Lime Industry | Metal Work | … |

Product detail pictures:

Related Product Guide:

Cooperation

With responsible good quality method, good status and excellent client services, the series of solutions produced by our company are exported to lots of countries and regions for Factory Free sample Herding Sinter Plate Filter - Cartridge-Sinter Plate Filter-Sinter Plate Dust Collector-Herding Sinter Plate Filter-Sintered Stainless Steel Filter Plate – Sinter Plate , The product will supply to all over the world, such as: belarus , Finland , Florence , To have much more enterprise. ompanions, we've got updated the item list and seek for optimistic co-operation. Our web-site shows the latest and complete information and facts about our merchandise list and company. For further acknowledge, our consultant service group in Bulgaria will reply to all of the inquiries and complications immediately. They're about to make their finest effort to meet buyers need. Also we support the delivery of absolutely free samples. Business visits to our business in Bulgaria and factory are generally welcome for a win-win negotiation. Hope to expertise a happy company co-operation perform with you.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!